What is InResST®?

As part of our commitment to sustainability, we use InResST® nylon in a range of our products. InResST® is a low-carbon, environmentally friendly company which focuses on the research, development, production and promotion of ocean plastics used in textiles, to give these plastics another lifecycle and reduce the amount of plastic in the oceans. Their mission is to reduce carbon emissions, reduce dependence on oil, protect marine life and environment and clean up the microplastic pollution in the ocean.

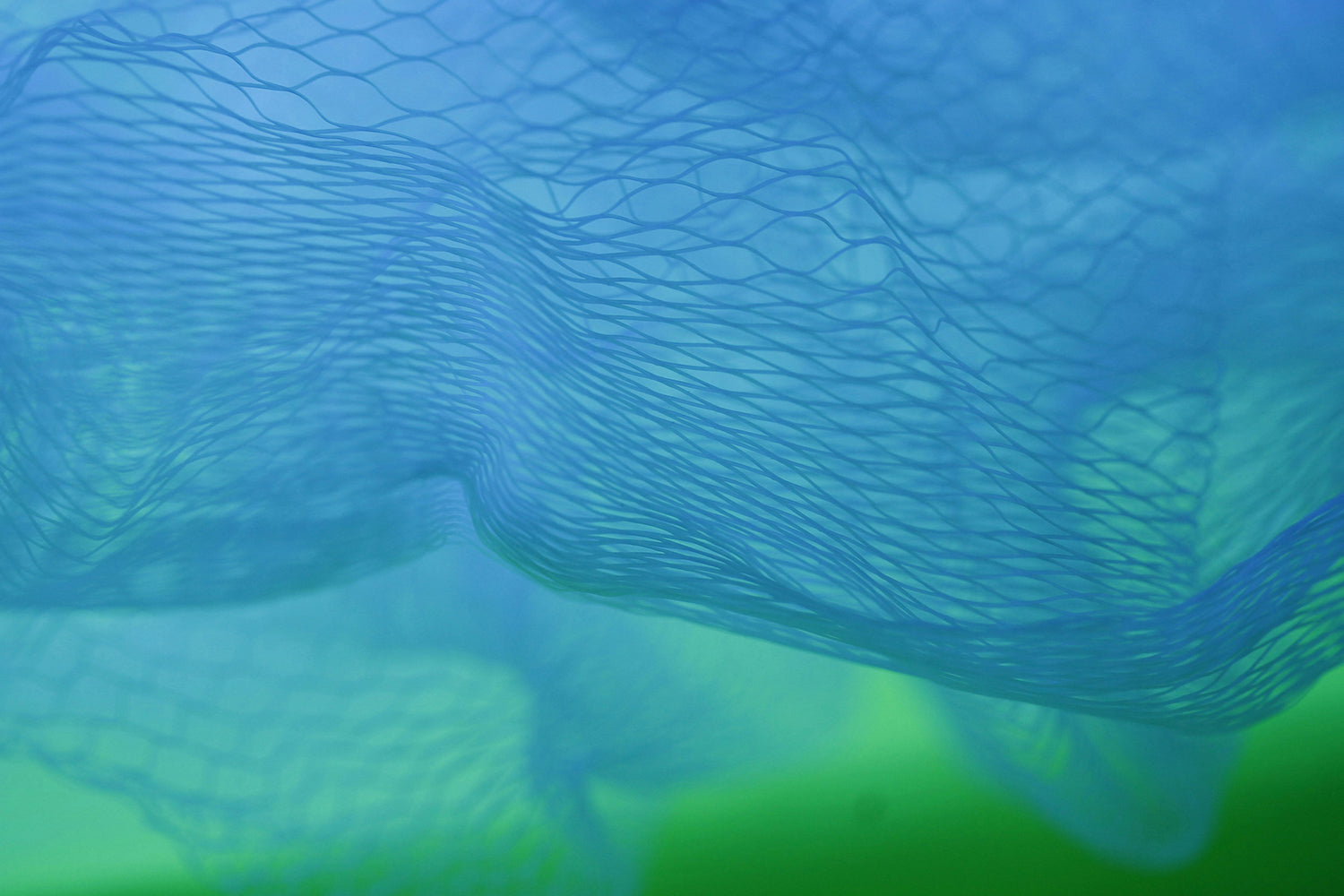

The problem with ghost fishing nets

A ghost fishing net is a fishing net that has been lost or abandoned in the ocean. These nets are left to trap anything in their path, including fish, sea turtles, dolphins, porpoises, birds and much more. They cause the animals to become trapped and entangled within the net, unable to move, causing injuries and preventing mammals and birds from rising to the surface for air. Hundreds of animals can fit into a single net – posing a very large threat to marine wildlife.

The fishing nets are not only harming animals, but they are also breaking corals, exposing them to disease and blocking them form the sunlight that they need. Ghost nets make up at least 46% of the Great Pacific Garbage Patch and take a very long time to break up. If they do break down, they become much smaller plastics that fish then ingest believing it is food – causing harmful toxins to go into their bodies and preventing them from being able to eat.

Why we use InResST® nylon

Sherpa has a dedication to continually improving the sustainability of the business and part of our commitment to protecting the earth involves working with and using other sustainable businesses like InResST® to produce sustainable, comfortable and practical clothing.

Process of making InResST® nylon

Making InResST® nylon is a four-step process. It involves recycling, regeneration, production and application.

- Recycling: InResST® starts by reclaiming nets used in deep-sea fisheries and offshore aquaculture, as well as rope material from shipping operations. This is done by encouraging fishing participants to bring back the used nylon nets by purchasing them on the market.

- Regeneration: This step is where the ghost fishing nets are made into sparkling clean chips through the efficient, scientific production of zero carbon factories, making the nylon ghost fishing nets into recycled nylon.

- Production: Recycled nylon gets processed into yarns and polymers inside the zero-carbon factories. The recycled nylon can be blended with cotton yarn, viscose, polyester, wool etc. which can be used to make clothing textiles among other things.

- Application: This refers to the manufacturing process, where the recycled nylon is used to create brand new products such as clothing, giving a new lifecycle to the nylon fishing nets.

Impact of using InResST® nylon

There is a significantly positive impact of using InResST® nylon, it helps to combat the plastics being left in the ocean and it gives a new lifecycle to fishing nets. It also massively helps the environment as each ton of InResST® raw material produced, saves 91% more carbon emissions, 90% more energy and 95% more water than virgin nylon.

To learn more about InResST® visit their website here